Green Translucent Geopolymer Concrete

About the Practice

Waste generation, stops exploitation of energy

Detail:

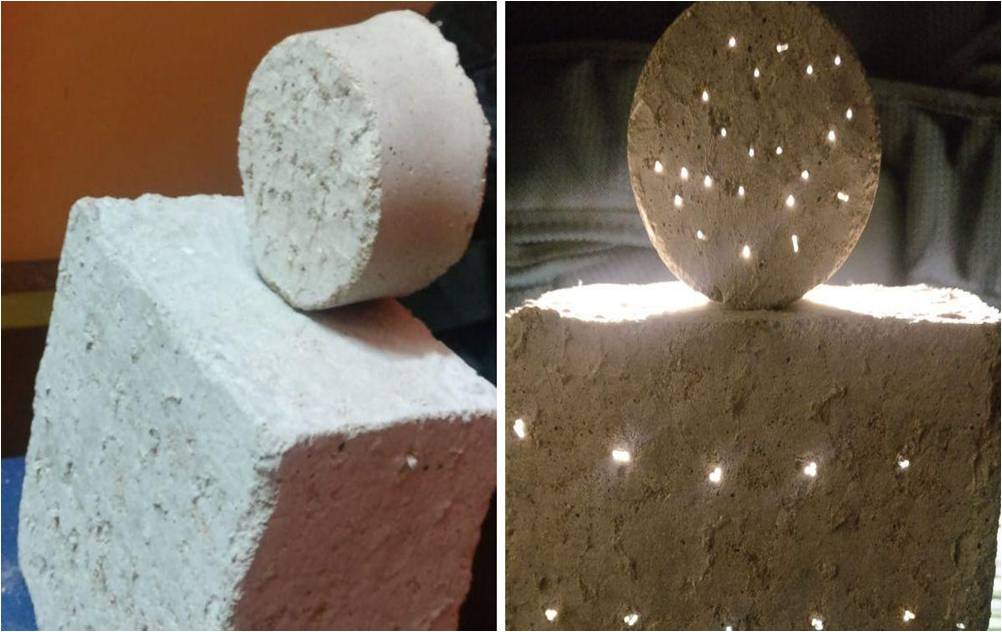

This eco-friendly alternative translucent geopolymer concrete has many qualities to support its claim to be better than cement. The cement present in the concrete mixture has been partially replaced with Ground Granulated Blast-furnace Slag (GGBS), which is a waste product of the iron & steel industry. This solves waste-management problems associated with furnace slag, while reducing the carbon footprint of cement use.The concrete mixture also contains plastic optical fibers that provide the translucent effect to the product without compromising strength. The concrete’s translucent property allows light to enter buildings without adding heat from the walls. In a developing country like India, where construction projects are taking place all over cities and rural areas, this product could be used instead of regular concrete or bricks.The walls can transmit up to 13% of the incident light, depending on the number of optical fibers used. This will enable greater energy saving and reduction in electricity bills, as there would be no need for lights during the day. This product reportedly claims to cut electricity costs by almost 30%. Furthermore, a reduction in electricity requirements would indirectly reduce CO2 emissions from primary sources of electricity generation. Ramansh adds that this translucent geopolymer concrete can be used for commercial buildings as well as small houses.This eco-friendly product comes as a relief for those who live in slums, where the concrete used is of poor quality and people cannot afford to pay their electricity bills. This translucent geopolymer concrete is 15% stronger, 5% lighter and costs 15% less than other competitors of the same. In areas with closely-packed buildings, this product can only be used for rooftops and window panels to allow enough natural light into the houses. Source: https://www.ecoideaz.com/innovative-green-ideas/ramansh-bajpai-innovates-eco-friendly-translucent-concrete

About the Innovator

Address: 15,GF Deendayalnagar, Kanpur U.P.

City: Kanpur

State: Uttar Pradesh

PIN Code 208002

Email: ramanshbajpai786@gmail.com

Contact No: 8005384640.999999

Practice Details

Link: High yield (i.e. 350 q/ha) Strong adherence skin of bulb Globular bulbs with good thickness of rings Single predominant number of axe and symmetrical cross section Tolerant to stem phythium blight High germination percentage (98%)

Manufacturing Capacity: c) Sub-contracting

Photo Links:

Blog Link 5:

- The Better India

https://www.thebetterindia.com/192332/kanpur-engineer-cheap-transparent-concrete-eco-friendly-innovation-india/ - Gulf News

https://gulfnews.com/world/asia/india/india-uttar-pradesh-boy-develops-transparent-concrete-for-buildings-1.65846553 - Outlook India

https://www.outlookindia.com/newsscroll/up-boy-develops-transparent-concrete-for-buildings/1597772 - INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH

https://www.ijstr.org/final-print/apr2018/Application-Of-Transparent-Concrete-In-Green-Construction.pdf - India Today

https://www.indiatoday.in/education-today/news/story/up-boy-makes-cheap-transparent-concrete-which-allows-sunlight-but-not-heat-can-reduce-electricity-use-by-30-1581405-2019-08-16

- Transparent Concrete

https://www.researchgate.net/publication/327720126_Transparent_Concrete