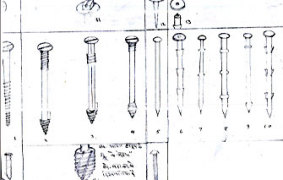

Novel Wood Screw

About the Practice

Screw foe Woods

Detail:

The innovation is a wooden screw, which has combined the features of the conventional wooden screw (threaded conical front) and metal stud (constant pitch intermediate thread). The novel screw thus comprises a head portion provided integrally with the body portion. The screw is tapered at the tip and the remaining portion possesses constant diametrical threaded pitch like the conventional metal screw/stud. The thread portion has a combination of common threads being provided on the body portion along with special kind of threads being provided at an inclination with respect to the common thread. There is also an unthreaded portion along the constant diametric length like the stud used in engine head. The heads are slotted so that they can be driven by a screw driver. This screw has an advantage of cutting its own threads when it is being screwed in for fastening purpose. Due to the use of Seller’s /ACME type of threads, stress concentration becomes less and thus reduces subsequent failure (cracks) that occurs in the wo

About the Innovator

Address: Vill. Kashipur Po. Panchkot Raj

City: Puruliya

State: West Bengal

PIN Code 713 102

Practice Details

Link: The tapered and threaded head of this screw facilitates easy movement into the work piece. Less effort is required to drive it in. Wood would also not crack while drilling (driving) in the screw. The screw will not become loose after some time, as it is broader at its tip and the cross sectional wedges around the screw (3-4) give it a better locking mechanism or grip. Even if the head breaks, the screw can be pulled out due to modified head configuration. A combination of inclined thread provides better gripping capacity and it requires no tapping unlike conventional metal screw.

Manufacturing Capacity: Yes

Problem Scale: Mild with local application